-

Content Count

64 -

Joined

-

Last visited

Posts posted by Burn! Motorsport

-

-

I'm not really sure what you are disagreeing about?

I never do more than ten minute sessions on track. The only exception being the allocated 15 minutes we had at Lydden Hill this year, where my brakes were smoking, but at that point still working fine.

So I wil reiterate my earlier point that if you stick to around ten minutes at a time on track then the stock pads are absolutely fine.

I think the standard pads are 'proper' pads plus I managed nearly 40K miles on them including a number of trackdays and sprints and 11 passes of the Alps! So in that respect they are very good indeed. I wonder how long these aftermarket pads will last?

I miss read your post. I thought you said "cheap option will do for short sessions" implying that the set up I suggested wouldn't be suitable for more than ten minutes. Sorry my bad. :bangheadonwall

Lauren reacted to this -

Good stuff :-) will be great for some feedback.

-

Cheap option is to do shorter on track stints. Stock discs and pads will take a 10 minute track session no problem. 15 minutes and they smoke. That's what I do.

I disagree. An upgrade to some proper pads will be more than sufficient for most here.

Just checked the standard disc sizes out as I thought they might be useful for this thread.

Front 294 x 24 vented

Rear 290 x 18 solid

IMO they are pretty decent sizes. If you are looking to do longer track sessions then a simple upgrade to the pads and discs will be more then capable. At that point if you are cooking discs then upgrade the discs to a higher carbon heat treated discs.

A bigger disc is not always better. It may manage more heat but it will inevitably weight more, cost more and be more likely the cause for a wheel upgrade.

If money is no object then high end BBK's will obviously be the choice. However I have many times seen cars with poorly balanced brakes being outperformed by well balanced standard set ups with well chosen pads.

-

Just a quick note to say we can supply braided hoses and brake fluid too!

-

I would say if your discs are still good then just go with upgraded pads, hoses and fluid. To retain the balance of the brakes you MUST match front and rear at the same time.

You do this relatively cheaply. Decent 5.1 fluid £12, Brake lines £70 and then Pads... well you could spend £300 up but its probably not necessary yet. Avoid pads that are labeled as "race" they will not perform when cold and greatly increase wear rates on the road.

Posting commercially I would recommend looking at

DIXCEL ES or Z type pads, check out this thread http://www.gt86.org.uk/forums/topic/2139-introducing-dixcel-brake-pads/

-

Where are you located?

Do you have a garage in mind for installation, or would you be confident installing yourself?

Can you carry out the works and complete a write up within 2 weeks?

I would suggest a process of:

1. GEO check - Adjustment shouldn't be necessary if correctly aligned already, just a print out to show current set up.

2. Vehicle test drive

3. Install Collars

4. GEO check and print out after collar installation. Then adjust to manufacturer specification or as per initial inspection and print out.

5. Vehicle test drive

Obviously the whole installation would need to be documented with images. I am looking for a good honest report from someone that appreciates refined handling.

As in the post above. We are offering one front and rear set for testing.

Here are the installation instructions. They have been loosely translated to english!!!

-

Did anyone take up this offer in the end??

I noticed you put some photos of the fitting instructions on the first page, but I can't seem to find them to download and see just how much work is involved... Looking into the rear subframe mounts and so on it actually doesn't look too complicated and almost like nothing major needs to be removed - so I'm still interested

if no-one else has taken the plunge already of course

if no-one else has taken the plunge already of course

Could you please either post a link to download the fitting instructions, or post some larger photos so I can confirm my current thoughts

Cheers!!

Hello, no on has taken us up yet. Partly my fault. We have all the kits here now so shout if your interested.

During the patent application process (typically 18 months from the priority date for my patent applications) the patent application is published in order for others to make counter claims and potentially fight for dismissal.

Therefore, if it is patent protected, the manufacturer should list the patent or application number(s) associated to protect themselves - this should apply to materials as well as "concept".

Patent applications also take many years from concept to grant, so if the manufacturer only recently launched this product, I'd expect it still to be "patent pending" although the material used may well have a grant.

So, in short, "patent protected" is not the same as "not public/published" - in fact if it's patent protected, it will be public domain information.

Thanks for that.

-

Okay, unfortunately SkallyB cannot take us up on the offer due to work commitments. GT86Jay was interested so we will give him first refusal.

-

These are a total bargain at that price. GLWTS

-

Duty and vat will be about 24% in total. If it comes via a courier there will be a clearance charge of usually about £30 or 4% of the total bill. If it's by ems I think the charges are slightly lower.

From our experience marking down invoices to keep customs charges low can be bad news as it also means that the insurance value is reduced. So if it arrives damaged you can't claim for the full cost.

Hope this helps.

-

We have the 1.3 multijet sport. Was a brilliant little car. It was a shame it had such a lack of sound deadening.

-

Fair play to you guys at Burns Motorsport. The fact that you are offering a set FOC for evaluation is admirable.

If you prove me wrong I will take it on the chin and sing your praises once more. I may even buy a set for the front subframe?

I want to like you post but I have reached my quota for the day

I believe in the gear I sell. After fitting to a number of my own cars I can say I truly do believe in them. I installed them to my wifes Fiat 500 and it transformed it. NVH levels dropped significantly, enough for my wife to keep the car for a further two years before trading it in for a larger more motorway suitable car. Some cars the effects are less noticeable.

I'm not a gambling man but I will put my money where my mouth is.

chillismoke reacted to this -

Car look great in that first pic.

Great to have another trackday freak onboard

Lee reacted to this

Lee reacted to this -

Hi, thanks for taking the time to check out this post.

The name "DIXCEL" comes from a combination of two words, "deceleration and excellence".

For the last few years DIXCEL have been at the tops of the food chain when it comes to brake discs and brake compounds. Unlike many of the other high end Japanese names like Project Mu and Endless, DIXCEL concentrate only on producing the highest quality breaking compounds and disc rotors.

Using their extensive racing experience and research and development DIXCEL have created a diverse product range with a solution for every situation.

Here at Burn! Motorsport we are super excited to be expanding out stock range to include pads and discs for the GT86 / BRZ.

Since the beginning of 2014 DIXCEL have embarked on a manufacture backed racing project with the GT86. This is great news for us as the experience they gain on the circuit will be passed to us and their product range. Their development has already lead to new racing compounds being required that will be released later this year.

The street product line up as it currently stands

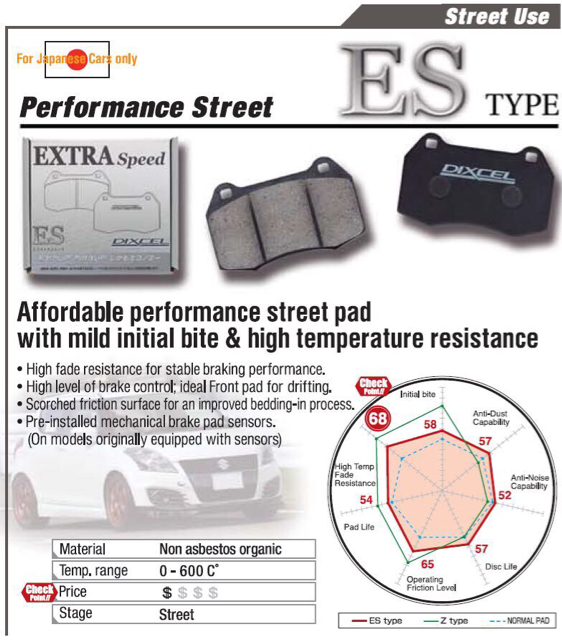

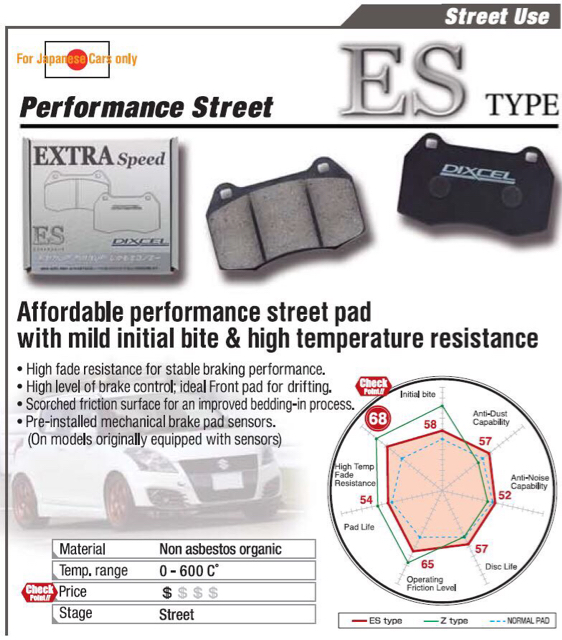

DIXCEL ES (Extra Speed)

Affordable performance! Great for the fast road user and can handle the occasional track day (novice drivers).

Front £66 inc vat

Rear £54 inc vat

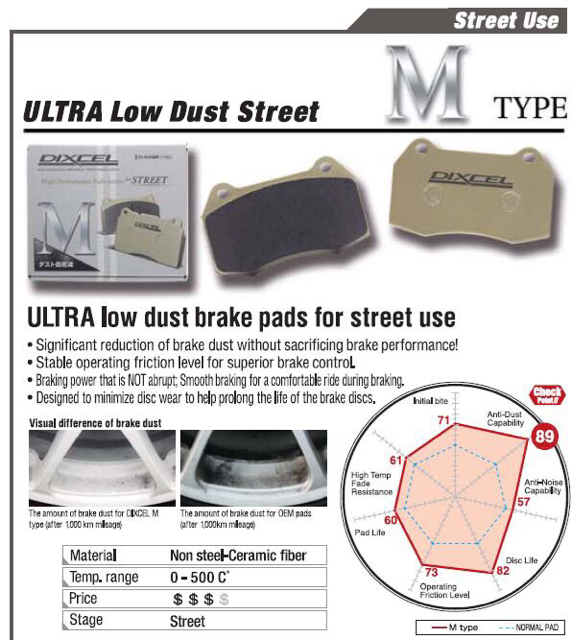

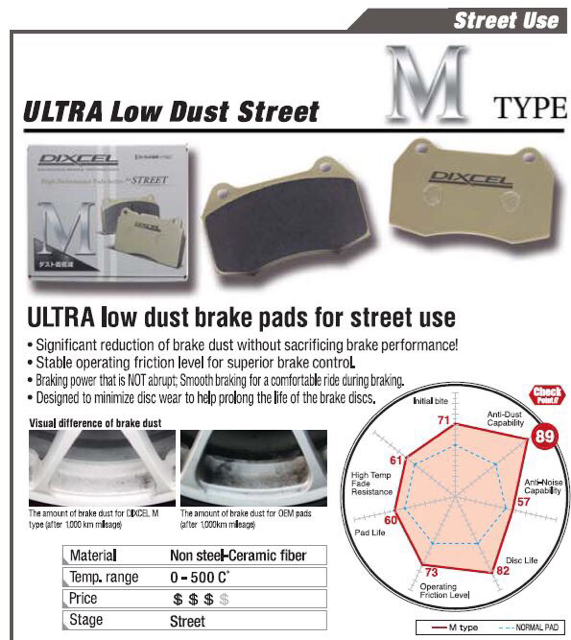

DIXCEL M Type (low dust and durability)

Don't like cleaning your wheels? These won't stop the dust but it's the closest you can get. Excellent durability, very quiet, kind on discs and great fast road performers.

Front or rear £156 inc vat

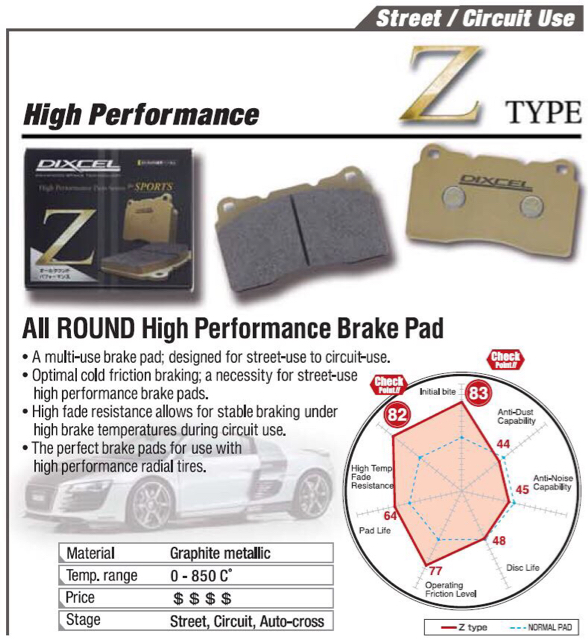

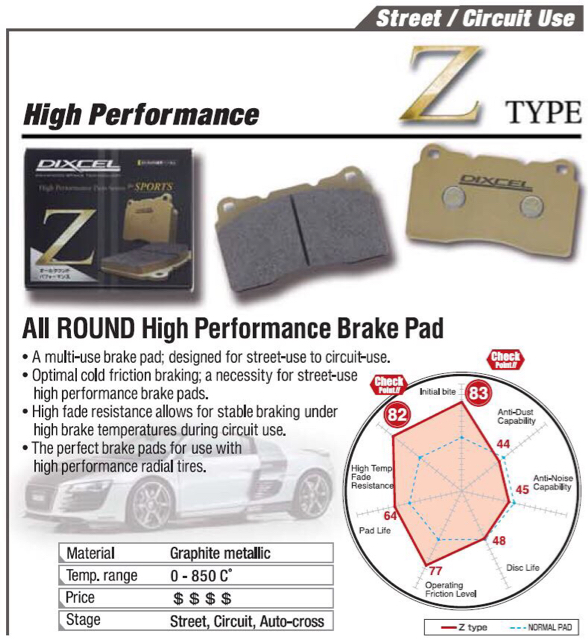

DIXCEL Z Type (street / track day)

Ultimate street / track day cross over pads. Temperature fade resistance of 850 degrees, excellent initial bite, excellent pad life and yet civilised. So good they have been used in one make race series around the world as the control pads.

Front £216 inc vat

Rear £198 in vat

Foulsmell reacted to this -

Surely step 1 should include adjustment to standard settings / personal choice, then step 4 re-adjusting to the same setting as previously used otherwise you are adding an extra variable to the test. As long as the alignment is the same before and after you have a control.

Good point. I made the assumption that the GEO would already be at the owners prefered spec's so adjustment wouldn't be required.

-

I'm up for this

Look like we have a volunteer!

Where are you located?

Do you have a garage in mind for installation, or would you be confident installing yourself?

Can you carry out the works and complete a write up within 2 weeks?

I would suggest a process of:

1. GEO check - Adjustment shouldn't be necessary if correctly aligned already, just a print out to show current set up.

2. Vehicle test drive

3. Install Collars

4. GEO check and print out after collar installation. Then adjust to manufacturer specification or as per initial inspection and print out.

5. Vehicle test drive

Obviously the whole installation would need to be documented with images. I am looking for a good honest report from someone that appreciates refined handling.

-

Here is DIXCEL's Race Car - they have just informed me that they have developed a new race only compounds so if any of you are racers let me know

-

Hi, thanks for all the comments. It's interesting seeing the reactions on these types of modifications on different forums. Introduce it to a forum where the members are already aware of issues with subframe movement and they are well received, introduce them where the cars are relatively new and benefits have not been explored then the reaction is always different.

I was also a skeptic when the product came on to our radar. However the product proved itself and I am no more.

Regarding the "secret space metal" comments, it's a joke... It is obvious to anyone with a engineering background that the material is an aluminium alloy. However we do not know which one as quite rightly so, it is patent protected like the concept of the product itself.

I am not hugely familiar with the GT86 yet as it is new to me so I am not going to argue the credentials without proof. However what I am willing to do is offer a set for the purpose of write up. The car would be better with un-modified chassis and suspension. i.e. no updated bushing or aftermarket suspension. However if its lightly modified then it's not the end of the world. A road test will be required before and after the installation, along the same roads and driven in the same manner. The car will require a GEO with print out before and after the installation - some adjustment may be necessary. This will need to be done pre road test. The installation will need to be documented and photographed for write up purposes. If your interested let me know.

-

Hi.

We are new traders in here but we can supply DIXCEL brakes. They are knocking the socks off all the other big brands in Japan at the moment.

I have three suggestions. If you don't track, then the DIXCEL ES pads will be perfect. Low dust, low noise, high performance and durable. These will work fine on track for the more novice driver - more experienced drivers and driver with R rated rubber should look at Z type pads.

They are cheap too. From £64.00 inc cat for the front and £55.00 for the rear.

If you are looking specifically for low dust the the DIXCEL M type would be up your street.

These are very hard wearing pads with fast road credentials. They are extremely low dust however it's impossible to eliminate dust. More expensive initially but you will get plenary of life out of them. £150.00 inc vat for front or rear

If you are more of a track hooligan we have the perfect track / street crossover pad. Incredible initial bite and controllability with a fade resistance of 850 degrees C. Being a street pad they work from cold so none of this warming up nonsense - you can feel confident letting your less experienced other half drive the car.

They produce less dust than OEM when street driven, civilised and refined in their behaviour. More expensive again but worth it if you are looking for a pad that can do everything. Front £216.00 rear £185.00

Let me knew if you have any questions. :-)

Kodename47 and chillismoke reacted to this -

Humm had trouble accessing the forum and posting a new topic today from my browser so I have posted this from tapatalk. I wondered if that's caused the issue. Saying that the post looks great with on here but it has embedded the links.

Any ideas mods?

Edited for spelling errors

-

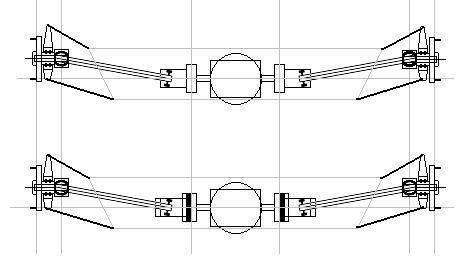

Hi, thanks for taking the time to read this post.

Firstly "what are they"..

Rigid Collars are individually designed and verified collars that align the bolts that hold the subframes or other suspension components to the chassis. The best way to get an understanding for them is to watch the video in this link below.

http://youtu.be/zWyUD6UXfog

Very recently there has been a featured Scion FR-S (GT86 BRZ) tuner challenge in the USA for SEMA 2014. One of the cars built by MOTOIQ installed them but also made a little video about the installation. Check out the link below.

http://youtu.be/WgkAImPh0yg

"What's in the box"

"Where do I get them"

Just follow the link below, stick in your car details and then use this code GT86CLUB to get 10% discount.

www.rigidcollar.com

If you buy both the front and rear set together a further 10% will be applied. Meaning a discount of 20%!!!!

Any questions let me know. -

Hey, where can we find out more about this? Is there a website?

-

Here at Burn! Motorsport, as the Distributor for DIXCEL in Europe we love brakes and the science that makes them work. When taking on the Distribution we spent a lot of time learning about how they work and how to best make your choice in pad and disc.

Over the next few days I hope to post some useful information about what we have learnt from our guys in Japan.

Firstly the Brake Pad

When you exceed the capability of the OEM brake pads it's best to replace for something that better suits your needs and applications.

There is often a misconception that you need to go to a 'race compound' to improve the braking performance. This is not true and race products shouldn't be used on the road - they can be very damaging to the rotors when outside the correct operating temperatures, which causes excess ferrious dust, noise and premature failure of the rotors.

Coefficient of friction is the measure of the ratio of the force of the friction between two surfaces and the force pressing them together. This matters because if you have too much then the brakes are very hard to control and if you have too little you won't be able to achieve enough braking performance to stop. It is important to find a pad that has suitable coefficient of friction whilst being able to maintain it at various temperatures, allowing it to reach its coefficient of friction as soon as you stamp on the pedal.

Fade resistance is the next characteristic to consider. Brake fade occurs in high temperatures when resin material in the pad vaporises. This creates a film between the pad and rotor reducing coefficient of friction. In general an OEM pad will have a fade resistance of about 300-350 degrees Celsius. Performance pads obviously have a much higher fade resistance, but this can come with an issue. Many high performance pads will only stabilise when they exceed a certain temperature giving poor performance from cold.

When choosing pads another common misconception is wear. People tend to believe that when you use a performance pad it will are faster. This is neither true nor false. This is because pad wear rate is different at different temperatures. A performance pad will be more resistant to wear at higher temperatures and an OEM pad will be more resistant at lower temperatures. You need to chose the pad that suits your type of driving best. This chart below shows different pads wear rates under different temperatures

Brake Rotors (discs)

Brake rotors are a little less complicated as the same rules of Coefficient of Friction that apply to the pads also apply to the rotors, but with rotors they don't really come in too many different compounds. With brake rotors it is about choosing the best rotor for your application. A basic OEM rotor will conform to certain tolerances, when an OEM rotor is exposed to more extreme forces the rotor may become unstable and a suffer warpage or cracking - This is caused by weaknesses in the Residual Stress.

Residual Stress is a structural weakness that occurs in the casting process of iron, the main material used in brake discs. During normal street-use, residual stress does not cause any problems with the discs. When the discs are used at race circuits at high temperature conditions for an extensive amount of time, the residual stresses within the disc can lead to thermal cracking and deformation. Residual stress is relieved by a heat treatment process to prevent thermal cracking and deformation from occurring.

Heat Treatment Process can be applied to any discs to relieve the Residual Stress from the casting process. We offer The DIXCEL heat treated discs to customers planning on using their car on the circuit. The advantage of the heat treated disc is increased durability.The heat treated discs have better protection against thermal cracking, juddering, and distortion.

The DIXCEL heat treatment process takes place over a 24 hour period. Starting from room temperature the heat is stepped up very slowly until the optimum temperature has been reached and then held for a number of hours and finally the heat is reduced again very slowly.

The result is a far more stable disc for circuit use. The chart below shows a comparison of heat treated vs non heat treated.

non-heat treated disc heat treated disc Crack resistance When a one-make series Honda DC5 Integra is driven at 2min 10sec/lap on the Motegi race circuit Hairline cracks occur on the braking surface after 1 hour of use. Hairline cracks occur on the braking surface after 2 hours of use. When an street legal Honda DC5 Integra is driven at 2min 20sec/lap on Motegi race circuit Hairline cracks occur on the braking surface after 2 hours of use. Hairline cracks occur on the braking surface after 5 hours of use. Judder resistance When a one-make series Honda DC5 Integra is driven at 2min 10sec/lap on the Motegi race circuit Minor juddering (vibrations) occur after 1 hours of use. Minor juddering (vibrations) occur after 2 hours of use. When an street legal Honda DC5 Integra is driven at 2min 20sec/lap on Motegi race circuit Minor juddering (vibrations) occur after 2 hours of use. No juddering (vibrations) occur after 4 hours of use.

Cast Iron and Carbon are the two main Brake Disc Materials. The benefit of carbon is its excellent high thermal resistance and it is lightweight. But as it is very expensive it generally only gets used by race teams and in high value motorsport. DIXCEL have chosen their own cast iron mix which is higher is carbon content than your run of the mill OEM disc. They also offer a 20% Higher Carbon mix in their FCR FP/FS series of discs that have been heat treated. These are more expensive due to the high carbon content but they are much more durable on the circuit and resistant to cracks and warpage. The FCR FP/FS rotors were developed for endurance racing and under severe conditions. They have excelled and are now the favorite among many race series around the world.

Slot or not to Slot

That is the question! Generally more slots the higher operating friction level, but increases air noise and faster pad wear.

It is another common misconception that to increase the performance of the brakes you must run slotted rotors. However we often recommend plain rotors to customers with the correctly selected pads to exceed their braking performance needs. Often much better value for money can be achieved using a plain rotor as it will not wear out the pads as quickly.

If you run them then which direction to run your slots?

If you made it this far well done! We could have gone into much more detail. However i do tend to bore myself sometime so I dread to think what you guys must think of me!

Any questions fire away!

Anthony

Keethos and chillismoke reacted to this -

Rob,

When you lower a car, you are basically moving the diff down closer to the road and adding angle at the driveshafts. Obviously this will increase CV joint wear. It's always best to keep the driveshafts as parallel as possible to the ground.

From my experiences with the S2000's rather than raising the differential to prevent it premature failure it was possible to just space the driveshaft on the inner CV joint to spread the shafts and limit the excessive movement wear. Maybe this could help? It's a reported problem on other forums too.

Best Brakes

in Modifications

Posted · Report reply

The ES would outlast the OEM. The Z's probably wouldn't but there would be no need to pull off the track every ten minutes.